Description

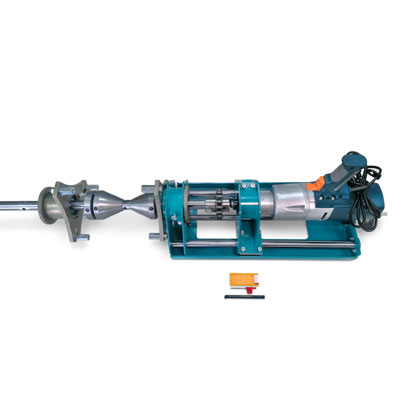

Mobile boring machine for axle repair ARBOR

Our machines allow you to repair axles, stockings, bridges, balancers.

WITHOUT REMOVING the bridge.

Description of the operation of a mobile boring machine for axle repair.

- Easily mounted on a damaged unit.

- Works in the field.

- No complicated electronics.

Description of the operation of the mobile boring machine ARBOR.

The boring bar is centered coaxially with the hole being processed and secured using two main supports; a longitudinal feed carriage with a drill is installed on one of the supports. A 2 kW drill ensures rotation of the boring bar; the rotation speed is adjusted in two stages: 330 and 500 rpm. The longitudinal feed of the boring bar with the cutter is carried out manually or using automatic feed. The basic kit includes everything necessary for work.

Specifications of the mobile boring machine ARBOR.

| Boring diameter | 32 – 115 mm. (can be increased according to specifications) |

| Boring length | up to 150 mm. (can be increased according to specifications) |

| Feed speed control | manual |

| Speed control | depends on the electric drill |

| Spindle reverse | depends on the electric drill |

| Processing accuracy | H7 |

| Drive power | 220 V, 50 Hz |

| Roughness | 1,6 Ra |

Advantages of the mobile boring machine ARBOR.

- With a mobile boring machine you can repair: mini excavators, backhoe loaders and excavators of all types.

- Easily mounted on a damaged unit.

- Works in the field.

- No complicated electronics.

Complete set of MOBILE BORING MACHINE ARBOR

- Main module (Shaft grooving) 1 pc.

- Centering device 1 pc.

- Installation nut M22x1.5 1 pc.

- Running axle of the machine 35(50*)x230 mm 1 pc.

- Set of threaded copiers (1.5/2 left/right) 1 set.

- Boring head with holder (tool holder) 1 pc.

- Tool holder extension 1 pc.

- Pulley for drill 1 pc.

- V-belt 1 pc.

- Set of carbide inserts 1 pc.

Video of the mobile boring machine ARBOB in operation

Reviews

There are no reviews yet.